TRAINING REPORT

| Title of the Training | Training on Coffee Harvest |

| Date of the training | 9th-19th January 2023 |

| Venue | Resource Centre, Ruzaphema |

| No of Batches | 3 Batches |

| Duration of the training per Batch | 3 days |

| Profile of the participants | District Project Officers, Asst. Project Officers, Asst. Inspectors, WDTs, and Coffee Growers |

| No of Participants | 95 Trainees 29 (Batch 1), 33 (Batch 2), 33 (Batch 3) (ANNEXURE 1) |

| Name of the trainer | Ms. Nathalie Manac’h, CEO & founder NAT Coffee, Mandalay, Myanmar |

| Topics Covered | Specialty Coffee productionIntroduction to Natural process Quality AssessmentProcessing: from picking to drying and storingReducing quality risk in processingClimate-neutral processing and the importance of exporting coffeeCreating Naga standard procedure for a trainer to a farmer |

DAY-1: Specialty Coffee production, Introduction to Natural process, Quality Assessment

Thetraining started with a self-introduction to avoid formality and maintain a cordial atmosphere. On the first day, participants were introduced to the core idea of Specialty Coffee, its importance, and how it is produced. The trainer has also imparted knowledge to process coffee in three processing methods.

A subject on ‘Specialty and Commercial grades’ was also discussed through a PowerPoint presentation where each participant was made to identify the two grades through pictures. The trainer also further clarified the distinctions between Specialty and Commercial coffee and that one of the noticeable differences lay in the packaging. Brands that produce specialty coffee always try to provide all the information about their product, unlike commercial coffee which contains limited information.

| Picking, sorting, and drying of ripe cherries on a drying station |

In the practical session, participants were formed into groups. Each group was assigned to sort the ripe cherries using the Natural process and lay them on drying stations. To maintain personal hygiene and sanitation while processing the fresh cherries, each participant received PPE (Personal Protective Equipment) such as gloves and masks.

| Center: Trainer demonstrating how to use Moisture Metre. Right: Participants learning to use Moisture Metre |

The last session of the day covered the topic of the need to test the moisture content of coffee seeds. In this session, participants learned the importance of using Coffee Moisture Metre in measuring the moisture level in the green bean which should ideally be 10 -12% as it can affect the taste, aroma, and overall quality of coffee. Too much or too little moisture can harm the coffee bean. Below 9%, coffee beans can burn while roasting. This tool is mandatory for quality assessment and indicates the time when coffee is ready for storage.

DAY-2: Field Visits (Processing: from picking to drying and storing)

All three batches were confined to field visits: Hukuto village (Batch-1), Nihoi village (Batch 2), and Lamhai village (Batch 3).

| Left: Trainer briefing the participants on the value of specialty coffee. Right: Selectively picking ripe cherries |

Each group was assigned the task of selectively handpicking ripe cherries which should be shiny, red, and firm to the touch. Coffee cherries shall also be spread out in the drying stations within 16 hours after plucking. The participants also learned the difference between Robusta beans and Arabica beans and were advised not to mix or plant the two types on the same farm. Specialty coffees are grown at a higher altitude having elevation above 1100 msl. The higher elevation, the better the aroma of the coffee.

| Examining if the cherries are suitable for Specialty Coffee. |

At the end of the field exercise, the trainer examined the cherries picked by each participant to see if they were suitable for Specialty Coffee. ‘Facts about coffee flowers and what they mean for producers’ was also covered. The coffee blooms can give an approximate estimated production in the next harvest season as the flowering nodes will later develop into coffee fruits. The more flowers in a tree, the more cherries a farmer can anticipate in the next harvest.

| Getting a hands-on experience in using Refractometer |

To determine the sugar content in cherry, the participants also had hands-on experience using a refractometer. The purpose of a refractometer is to help the producer determine the ripeness and sugar content of their cherries in percentage form. 20 to 23 degrees Brix is considered an average range for green coffee. If the fruit is ripe, it has more sugar content and if the fruit is immature, it has less sugar content.

DAY-3: Reducing quality risk in processing, Climate- neutral processing, and the importance of exporting coffee, Creating a Naga standard procedure for a trainer to a farmer

The main focus of the third day was to train the participants in understanding the conversion ratio of coffee cherries. Participants also learned to evaluate the fresh cherry to dried cherry, fresh cherry to parchment, fresh cherry to green bean, and conversion from green beans to roasted beans.

| Participants designing their coffee farms |

As part of the group exercise, the participants were also given the assignment to design their coffee farms considering the factors (climate, elevation, species, storage, intercropping pattern, shades) involved in establishing a coffee farm. Each group presented its ideas and strategies. Later on, based on their presentations, the trainer shared the feedback. Participants also shared their vision for the Nagaland Export Hub and expressed the future they wish to see in Nagaland coffee sector.

Certificate Distribution and Closing:

| Distribution of completion certificates to the participants from Batch-1 by Director, LRD |

| Distribution of completion certificates to the participants from Batch-2 by Jt. Director, LRD |

| Distribution of completion certificates to the participants from Batch-3 by Addl. Director, LRD |

At the end of the training, each participant submitted their feedback on their view about the training. A closing ceremony was held for the distribution of certificates to the participants on their successful completion of the 3-day training. The participants also shared their learning experiences as well and extended their appreciation to the trainer and the Department for organising such trainings

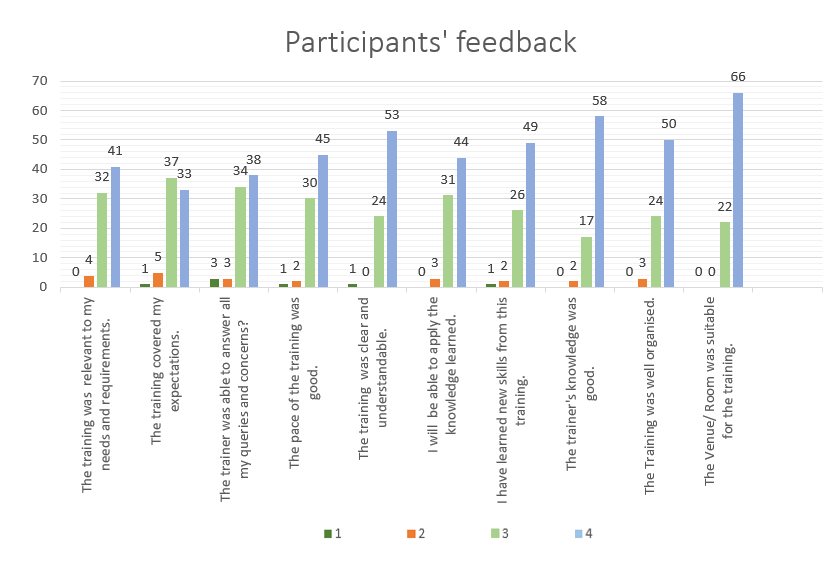

Training Feedback from the Participants:

With regard to the training feedback about the trainer, most of the participants responded the trainer’s knowledge to be good even though few of their queries and concerns could not be answered. Other aspects such as the pace of the training, training topics were well received by the participants. Majority commented that they have acquired new skills during the training and will be able to apply the knowledge learned.

| SCORES(4 being the highest and 1 being the lowest) |

ANNEXURE 1: PARTICIPANTS’ LISTS

| 1st Batch (9th – 11th January, 2023) List of Participants from the districts for Coffee Harvest training | ||||

| Sl. No | Name | Gender | District | |

| 1 | Akato Chishi | M | Nuiland | |

| 2 | Tovito Sumi | M | ||

| 3 | Tepunol Yore | M | Chumukedima | |

| 4 | Orenthung Odyuo | M | ||

| 5 | V. Vikugha Kiba | M | Zunheboto | |

| 6 | Agnes Phewhuo | F | Kohima/Tseminyu | |

| 7 | Sentinungla | F | ||

| 8 | Lipichem | M | Kiphire | |

| 9 | Lichumo Murry | M | Noklak | |

| 10 | Puso Thai | M | ||

| 11 | Kughalu Chishi | M | Longleng | |

| 12 | Dr Sashiyangba | M | Mokokchung | |

| 13 | Alemla Aier | F | Peren | |

| 14 | Rongsenkaba | M | ||

| 15 | Imlinochet | M | ||

| 16 | Yimkhong Siphong | M | Tuensang/Shamator | |

| 17 | Amos Khiam | M | ||

| 18 | Chosevoyi Dawhuo | M | Phek | |

| 19 | Novisie Kajiri | M | ||

| 20 | Tapa Konyak | M | Mon | |

| 21 | Thunglamo Jami | M | ||

| 22 | Yanthungo Tungoe | M | Wokha | |

| 23 | Thungdemo Yanthan | M | ||

| 24 | N. Kheshito | M | Zunheboto | |

| 25 | Shaklen | F | Longleng | |

| 26 | Dr Zewete Lekhro | M | ||

| 27 | Imlitula | F | Mokokchung | |

| 28 | Ngaungtola Yim | F | Tsg/Noklak | |

| 29 | Dr Kevizekho Kar | M | Kohima/Tseminyu | |

| 30 | Ketholeno Neikha | F | ||

| 31 | Vizekho | M | ||

| 32 | Alben | M | ||

| TOTAL PRESENT – 29 | ||||

| 2nd Batch (12th – 14th January, 2023) List of Participants for Coffee Harvest training | |||

| Sl. No. | Name | Gender | District |

| 1 | Samuel Holo | M | Nuiland |

| 2 | Inokivi Chophy Sumi | M | |

| 3 | Kitovi | M | |

| 4 | K. Tokishe Swu | M | Chumukedima |

| 5 | Chikhalu Ayemi | M | |

| 6 | Lhokishe | M | |

| 7 | Ngulminlen | M | Peren |

| 8 | Thulengsipi | M | |

| 9 | Iteibambe Hau | M | |

| 10 | Kimhoineng Guite | M | |

| 11 | Bendangsashi | M | Mokokchung |

| 12 | Sunep longkumer | M | |

| 13 | Benchulo | M | |

| 14 | V. Ango Phom | M | Longleng |

| 15 | H. Heipong | M | |

| 16 | K. Chingnyu | M | |

| 17 | Ngamching L | M | |

| 18 | K. Khamba Konyak | M | Mon |

| 19 | K. Anden Semon | M | |

| 20 | P. Khenyen | M | |

| 21 | Moba Konyak | M | |

| 22 | Chichamo O Tungoe | M | Wokha |

| 23 | M Libemo Kikon | M | |

| 24 | Chonben Murry | M | |

| 25 | Achomo Ngullie | M | |

| 26 | Kimiyekato Shohe | M | |

| 27 | K. Kekong Yimchunger | M | |

| 28 | Senshanthung Yim | M | |

| 29 | Mughashe Sumi | M | |

| 30 | Motsubemo Odyuo | M | |

| 31 | Suuvu Swu | M | |

| 32 | Kedidine Ntukmai | F | |

| 33 | P. Timong Tikhir | M | |

| 34 | Along Jamir | M | |

| 35 | Chumbeni Murry | F | |

| 36 | Imlikaba Phom | M | |

| 37 | Putisangba Chang | M | |

| 38 | L. Chenithung Kithan | M | |

| 39 | Vitsomenuo Pienyu | F | |

| 40 | Thejaneinuo Claudia Pienyu | F | |

| 41 | Sentilemzung | M | |

| 42 | Akangtemjen | M | |

TOTAL PRESENT – 33

| 3rd Batch (17th – 19th January, 2023) List of Participants for Coffee Harvest training | |||

| Sl. No | Name | Gender | District |

| 1 | Anilo Rengma | M | Tseminyu |

| 2 | Haiwalo Kath | M | |

| 3 | Kenneth Kath | M | |

| 4 | Kekhriezhakuo Miario | M | Kohima |

| 5 | Thejasatuo Zhaleo | M | |

| 6 | Thejasilie Kaco | M | |

| 7 | Thejanuo Kets | F | |

| 8 | Z. Daccato Sema | M | Zunheboto |

| 9 | Kiho Chishi | M | |

| 10 | Laboka M Chishi | M | |

| 11 | Jepika K Kinimi | M | |

| 12 | Sentimongba Sangtam | M | Tuensang |

| 13 | Y. Yentin Kejong | M | |

| 14 | Y. Kongpe | M | Noklak |

| 15 | T Lamthaio | M | |

| 16 | Bumoi | M | |

| 17 | Ayinla | F | |

| 18 | H. Ahoshe | M | Shamator |

| 19 | Elijah | M | |

| 20 | Jonathan | M | |

| 21 | Joseph Kiusumong | M | Kiphire |

| 22 | Thomas Kiumusu | M | |

| 23 | V. Atoholi Shohe | F | |

| 24 | Suluciyi Ringa | M | Phek |

| 25 | Mutukhru Rhakhu | M | |

| 26 | Theyehuyi Dawhuo | M | |

| 27 | E. Manihru Kahesu | M | |

| 28 | L. Asenla Walling | F | |

| 29 | Kakuto Assumi | M | |

| 30 | Kumtzuk Lemtor | M | |

| 31 | Chathavisie Tehruja | M | |

| 32 | Sinilo Kemp | M | |

| 33 | Athriti Sangtam | M | |

| 34 | Talirenba Sangtam | M | |

| 35 | Besukho Swuro | M | |

| 36 | Pfukupe Koza | M | |

| 37 | Lanchenthung Yanthan | M | |

| 38 | Easter Ngullie | F | |

| 39 | Kevilezo Rupreo | M | |

| 40 | Dr Vibeilie Mere | M | |

TOTAL PRESENT – 33

ANNEXURE-2: FEEDBACK FORM

ANNEXURE-3: TRAINING SCHEDULE

ANNEXURE-4: CERTIFICATE